PV Solar Module Clamp Gaskets & Seals

The energy needs increasing as the population, urbanization, and industrialization increase worldwide. Accordingly, energy sources have also diversified, among which renewable alternative energy sources are favored more.

It is a scientific fact that the current energy resources will run out in a very short time since the need for energy is increasing rapidly in parallel with the increase in world population and technological development.

To meet this demand, carbon-based fuels are used, which makes it impossible to keep the world's emission value within the current limits.

If the pollution continues to increase like this, negative consequences such as an increase in world temperature and a rise in sea level will inevitably occur. As a result, the use of renewable energy sources in energy production worldwide is of vital importance.

In recent years, the sun, a source of heat and light, has stepped forward among renewable energy systems. As a result of the increase in energy efficiency thanks to new technologies developed in Photovoltaics (PV) Solar Module technology, the number of solar energy panels in the world is increasing rapidly.

One of the reasons for the energy losses that occur in solar energy systems is the clamp seals that connect aluminum profiles on which PV Solar modules are mounted. The low electrical conductivity of the raw material to be used in the production of clamps is critical. The lower the electrical transmission coefficient, the more electricity obtained through the panels, which is prevented from being transferred to the ground over the chassis.

Since the panels will be exposed to the sun for a long time and at a right angle, the clamp raw material must maintain its high UV and ozone resistance, low permanent deformation, and flexibility for a long time.

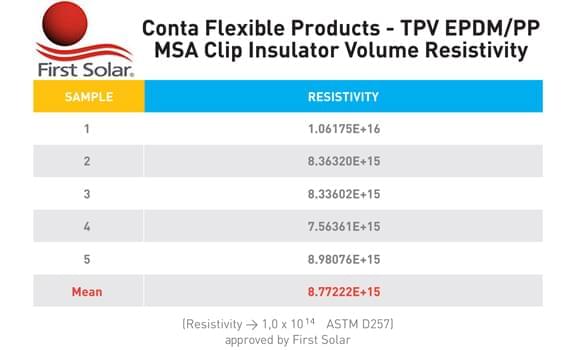

The TPV-based gaskets we produce for solar system clamps have been tested by "First Solar", the world's most important PV Solar Module manufacturer, and approved for Electrical Resistance panels.

Advantages

- Low electrical conductivity, First Solar approved.

- Environmentally friendly and 100% recyclable.

- It won't let you down! Thanks to its high UV & Ozone resistance, it withstands harsh weather conditions.

- Its dimensions do not change in hot or cold. It works seamlessly across wide temperature ranges.

- Can be produced as Co-Ex, and TPEs with different properties can be used in a single product.

- Highly resistant to permanent deformation and does not leak over time.

- Conforms to European Norms: ROSH, PAH, REACH.