Deepfreeze and Refrigerator Seals & Gaskets

Refrigerators that keep food fresh and meet the need for ice and cold drinks are indispensable for homes today. Foods such as meat, chicken, and fish, which spoils quickly, can be stored for a long time, mainly thanks to the freezer sections.

PVC is highly preferred for refrigerator gaskets and used in refrigerator doors/covers due to their heat transfer property. However, manufacturers and users are experiencing some difficulties due to some disadvantages arising from PVC's inherent properties.

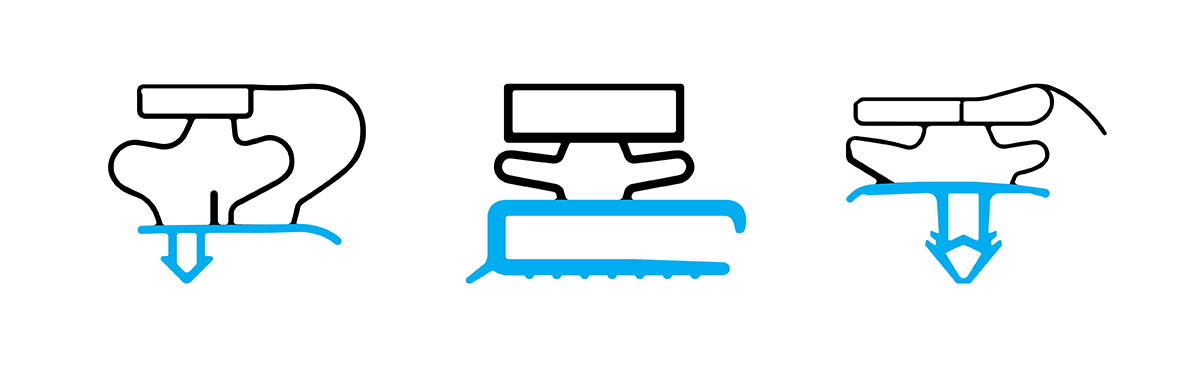

The TPE (Thermoplastic Elastomer)-based refrigerator and freezer gaskets we produce, both with and without magnet, offer both ease of use and low heat transfer advantages.

Since SEBS or EPDM structure provides softness to the TPE material, no hardening or tearing is observed over time, providing long-term resistance.

In addition, thanks to the rubber phase, it maintains its sealing feature without losing its flexibility even at -18 degrees.

Thanks to its low heat transfer coefficient, production costs are reduced while providing an advantage for energy classes.

Since TPEs are safe for human health and food contact, they are preferred over carcinogenic products.

Advantages

- Environmental friendly.

- It can be produced safely for human health and food contact.

- Maintains its flexibility even at low temperatures.

- There is no need for the hot-gas system used in refrigerators.

- Has a low heat transfer coefficient.

- No need for a conditioned environment during mounting.

- Easy to install.

- Excellent weldability.

- Low permanent deformation.

- High UV and Ozone resistance.

- Excellent resistance to cold/hot.

- 100% recyclability

- Wide hardness scale from 20 ShA to 65 ShD.

- Can be colored.

- Reach, RoHS, and PAHs compliance.